Party Logistics 1PL, 2PL, 3PL, 4PL, 5PL and 6PL.

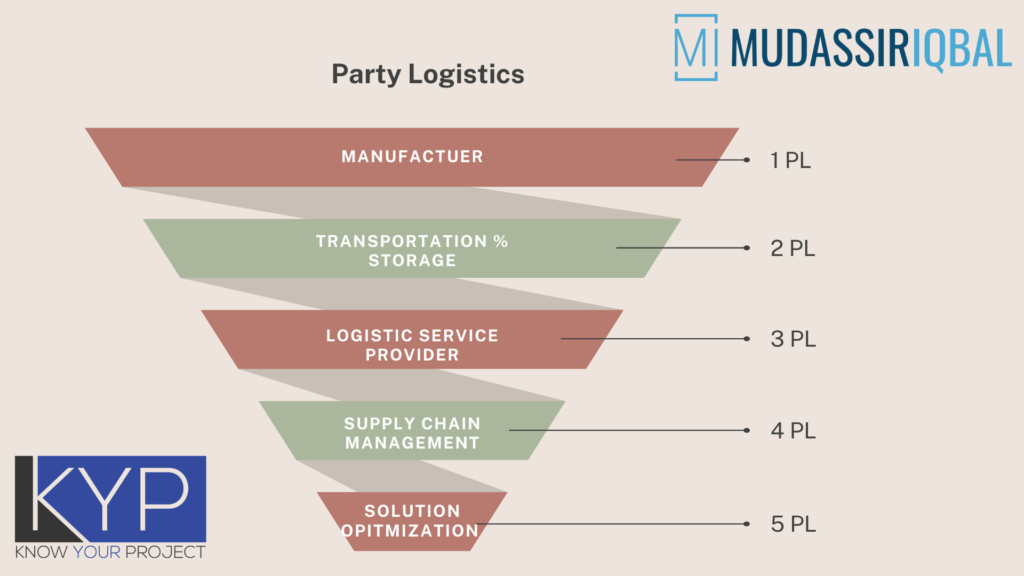

In the previous article, we talked about the difference between Logistics and Supply chain Management. In this one, I thought to take up a basic topic and introduce the topic of “Party Logistics” or as we call “xPL” i.e 1PL, 2PL, 3PL, 4PL, and 5PL

In today’s business environment, companies often rely on logistics service providers to manage the flow of goods and services. The provider’s role in the supply chain depends on its level of engagement with the customer

A company’s supply chain becomes increasingly outsourced and service integration becomes more prevalent as it advances from 1PL to 6PL (and beyond).

Based on its xPL classification, logistics service providers use a variety of tools to provide relevant and tailored advice to customers or their representatives. For example, they may use ERP software to track inventory levels and ensure that orders are fulfilled within acceptable timeframes. ERP systems are also used for managing fleets of vehicles or freight, as well as controlling inventory at warehouses or distribution centres.

1PL: 1st Party Logistics

The term first-party logistics (1PL) refers to a business or individual that transports and delivers its goods. No other companies will be involved in the transportation of the goods. For instance, a manufacturer may produce equipment and deliver them directly to the end locations via their vehicles. First-party logistics is also called in-house logistics, as the logistics companies are part of the same organization.

This method of delivery is common when a manufacturer wants to deliver its products directly to customers without using any other company’s resources. In this case, the manufacturer has the equipment (trucks, warehouses etc.) necessary to handle transportation and storage.

As a result, you could say that there are no other intermediaries in the entire process. The first-party logistics model was popular until the late 1970s when external providers started offering third-party logistics services.

2PL: 2nd Party Logistics

2PL stands for second-party logistics and refers to a company that provides logistics services in which they have ownership of the transportation that is used. They will also have their own warehouse space, staff, and equipment.

Freight forwarders, shipping companies, forwarders, and warehousing companies, as well as providers of a courier, express, and parcel services, are all examples of typical 2PL providers.

3PL: 3rd Party Logistics

Third-party logistics (3PL) is a growing field that has been in existence since the 1970s. The role of 3PL is to manage the complex supply chain system on behalf of companies that hire them.

The 3PL provider is fully integrated into their customers’ processes. They provide supply chain integration in the following ways:

- Transportation and forwarding of freight

- Warehousing and distribution services, including inventory management and cross-docking

- Labelling and packaging

- Clearance of Customs

- Returns and repairs can also be handled, and most importantly, invoices and payments can be tracked.

As a result, a manufacturer can outsource all of their goods’ transportation, storage, packing, and distribution to a single third-party logistics provider. The majority of third-party logistics companies are adaptable, allowing you to use as many or as few of their services as your needs dictate.

The 3PL service providers organize the flow of goods and information for their customers and take over their entire logistics processes and most often provide additional value-added services.

3PL services can be used to move products to and from retailers, wholesalers, manufacturers, and consumers.

Additionally, as eCommerce fulfilment continues to grow at a breakneck pace, small to medium-sized businesses are increasing their reliance on 3PLs which in turn result in advancements in tracking technology, such as AI-based vehicle management system

4PL: 4th Party Logistics

This new concept was established in the mid-’90s. A 4th Party Logistics solution entails the use of an independent, or ‘neutral,’ lead logistics provider who acts as an agent.

They are considered system integrators because they act as a link between their customers (typically OEMs) and other logistics service providers (often third-party logistics providers) to ensure the coordination and organisation of all business processes throughout the value chain. As a result, 4PL will include all of the benefits associated with 3PL providers, but will also include the following:

- Management of projects, sourcing, and negotiation

- Strategy and analytics in logistics

- Unbiased service advice

- A centralised contact point

Thus, the ultimate goal of a 4PL provider is to assume control and integration functions within the supply chain in the absence of its operating resources and to increase the supply chain’s efficiency. They rely heavily on a well-developed information technology infrastructure to ensure the integration of multiple external service providers.

5PL: 5th Party Logistics

5PL entails a fully integrated logistics solution that spans the entire supply chain from start to finish via a network of outsourced service providers.

At a 5PL, the primary functions of inbound and outbound logistics are managed by third-party suppliers. The 5PL is responsible for creating and maintaining a network of suppliers. The 5PL employs its staff to coordinate the activities of multiple service providers, including transportation and warehousing companies, while also providing value-added services such as containerization, routing optimization, equipment provisioning (such as pallets), payment processing and other financial services

Due to the 5PL solution’s emphasis on technology, it is well-suited for e-commerce.

In the end, how to decide what works best for you depends on questions like;

- ‘How much power do I want?’

- Can I handle it alone?

- ‘How expert am I?’

- Do I need to be flexible?

3PLs are ideal for outsourcing logistics while maintaining central control. 4PLproviders, on the other hand, provide higher levels of consulting, communication, and services, but total supply chain control is given up. This sometimes can lead to more efficient and cost-effective operations.

Partnering with an innovative leader can maximise customer value and competitive advantage. Successful logistics partnerships seamlessly integrate product and data flow.